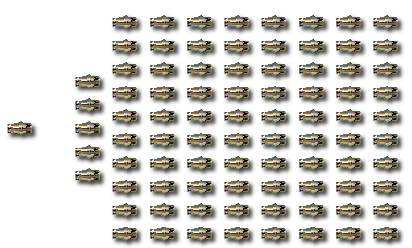

The FlowMate Wave, Pre-Set High Capacity Automatic Balancing Valve, is designed to balance high flow rates in heating and cooling circuits. Composed entirely of stainless steel, the integral FlowMate Wave cartridges are factory set and depending on size , up to 85 cartridges can be used in each valve. This offers a wide range of flow settings and a versatile solution to balance high capacity flow.

Automatic Balancing

Manual balancing is laborious, time consuming and requires unnecessary use of resources and if not done frequently and correctly, can lead to imbalances in the system. This results in needless use of time, labour and an inefficient system. With Automatic balancing valves such as the FlowMate Wave, the system runs efficiently and without the needs that manual balancing requires. Once installed, Automatic balancing valves maintain the set flow rate automatically, thus saving on resources and ensuring efficiency.

Benefits

- Precise Automatic balancing resulting in

- Minimized maintenance and downtime – The FlowMate Wave is designed to be hassle free in installation & operation.

- Greatly reduced commissioning requirements – saving time and resources.

- An efficient and & cost saving system- all ensure peace of mind for the end user.

- The easily accessible cartridge along with it’s easy flow rate setting procedure ensures quick and efficient system set up and tuning.

- High grade materials give durability and a long operational lifetime.

- With the elimination of manual balancing valves and branch piping, costs in labor and installation are dramatically reduced.

- Installation space is kept to a bare minimum with reduced equipment requirements.

Durable

The FlowMate Wave cartridge is manufactured to balance high flow rates with precision & durability.

Working Principle

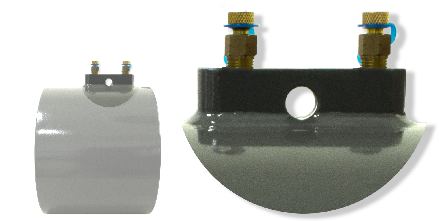

The FlowMate Wave cartridge maintains a set constant flow by means of it’s variable sized apertures and spring loaded mechanism, all contained within a cylindrical housing. The spring loaded housing acts as a piston regulating the apertures sizes, increasing or decreasing relative to fluid thrust within the system.

Constant flow is maintained by the variable sizing of the apertures through which the fluid flows; the aperture size variance is governed by the precision spring which acts against the amount of the fluid thrust. Each cartridge in the FlowMate Wave valve body works in unison, reacting against varying pressure and maintaining constant flow.

High Flow Control

By utilizing 1 to 85 precision calibrated cartridges, the FlowMate Wave accommodates multiple high flow control requirements.

Convenience

Lift & move the FlowMate Wave easily with this labour saving hoisting hole.

Features

- DN50 to DN800 connection sizes.

- Compact and robust design.

- Optional integrated PT Ports .

- Multiple Flow Cartridge combinations

- Unique valve design gives a higher than industry average DN size to flow rate ratio.

- Pre-set flow rate. the factory pre-set flow rate remains constant at ±5% regardless of varying differential pressure.

- The self-cleaning design of the FlowMate cartridge ensures that it’s functionality is not affected by any impurities in the water.

- High grade CNC milled stainless steel cartridge ensuring accuracy and longevity.

Use

Heating or cooling applications with high capacity flow can utilize the FlowMate Wave to limit and control their high flow rates. Applications including, but not limited to, cooling towers, pumps, chillers, heat exchangers and AHU’s can benefit from the FlowMate Wave’s automatic balancing functionality.

Available Sizes

| DN50 | DN65 | DN80 | DN100 | DN125 | DN150 | DN200 | |

| DN250 | DN300 | DN350 | DN400 | DN450 | DN500 | DN600 | DN800 |